Lift Check Valvehukum2017-09-21T12:41:28+00:00

Application Standards:

- Design & Manufacture confirm to ISO 17292

- End Connection Confirm to

- Socket weld Standard:- ASME B16.11

- Screwed end standard:- ASME B1.20.1

- Butt-weld standard:- ASME B16.25

- Flanmge End Standard:- ASME B16.5

- Face to Face standard:- ASME B16.10 / mfg.

- Testing Standard: API 598 / EN 12266-1

- Pressure & Temp. Rating Standard:- ASME B16.34

- Structure Features

- Bolted Cover

- Welded Cover

- Material Confirms to ANSI / ASTM

- Carbon Steel:- A105, LF2

- Alloy Steel:- F5, F9, F11, F22, F91

- Stainless Steel:- F304L, F316L

- Duplex Steel:- F51, F53, F55

- Special Grades:- INCONEL 625, MONEL K400, ALLOY 20

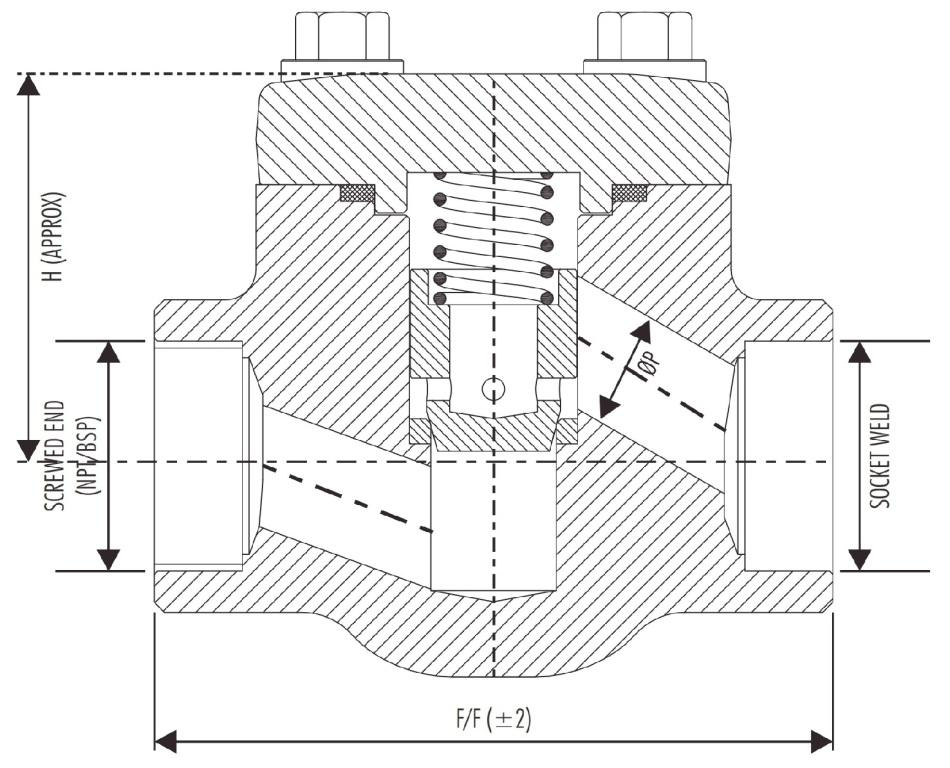

| CLASS 800# |

| SIZE |

F/F |

øP |

H |

WT (Kg) |

| 15 mm |

87 |

9.5 |

53 |

1.0 |

| 20 mm |

92 |

12.7 |

56 |

1.3 |

| 25 mm |

106 |

17.5 |

66 |

2.2 |

| 32 mm |

127 |

23.8 |

86 |

4.9 |

| 40 mm |

127 |

28.6 |

86 |

4.7 |

| 50 mm |

142 |

36.5 |

104 |

8.2 |

| CLASS 1500 # |

| SIZE |

F/F |

øP |

H(O) |

WT (Kg) |

| 15 mm |

92 |

8.0 |

56 |

1.5 |

| 20 mm |

106 |

9.0 |

66 |

2.5 |

| 25 mm |

127 |

14.0 |

86 |

5.6 |

| 32 mm |

127 |

20.0 |

401 |

5.4 |

| 40 mm |

142 |

25.0 |

104 |

9.4 |

| CLASS 2500 # |

| SIZE |

F/F |

øP |

H(O) |

WT (Kg) |

| 15 mm |

106 |

7.0 |

66 |

2.9 |

| 20 mm |

127 |

12.5 |

86 |

6.4 |

| 25 mm |

142 |

15.5 |

104 |

10.8 |

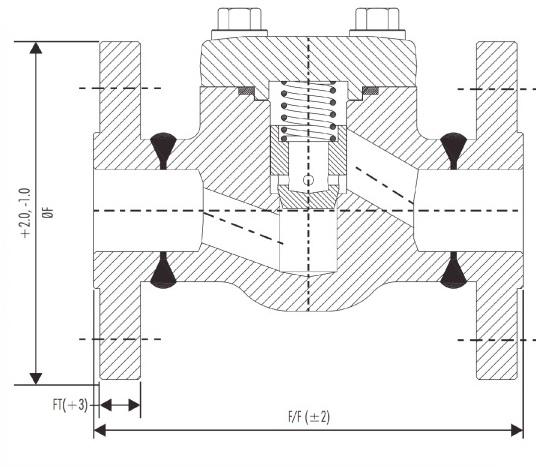

| CLASS 150# |

| SIZE |

F/F |

ØF |

FT |

WT (Kg) |

| 15 mm |

108 |

90 |

9.6 |

2.0 |

| 20 mm |

117 |

100 |

11.2 |

2.9 |

| 25 mm |

127 |

110 |

12.7 |

4.2 |

| 32 mm |

140 |

115 |

14.3 |

7.3 |

| 40 mm |

165 |

125 |

15.9 |

7.9 |

| 50 mm |

178 |

150 |

17.5 |

13.4 |

| CLASS 300 # |

| SIZE |

F/F |

ØF |

FT |

WT (Kg) |

| 15 mm |

140 |

95 |

12.7 |

2.8 |

| 20 mm |

152 |

115 |

14.3 |

4.1 |

| 25 mm |

165 |

125 |

15.9 |

6.0 |

| 32 mm |

178 |

149 |

17.5 |

9.3 |

| 40 mm |

190 |

155 |

19.1 |

10.9 |

| 50 mm |

216 |

165 |

20.7 |

16.0 |

| CLASS 600 # |

| SIZE |

F/F |

ØF |

FT |

WT (Kg) |

| 15 mm |

165 |

95 |

14.3 |

3.0 |

| 20 mm |

190 |

115 |

15.9 |

4.2 |

| 25 mm |

216 |

125 |

17.5 |

6.4 |

| 32 mm |

229 |

149 |

20.7 |

10.1 |

| 40 mm |

238 |

155 |

22.3 |

11.9 |

| 50 mm |

292 |

165 |

25.4 |

18.0 |